Technical

Understanding

Mentality

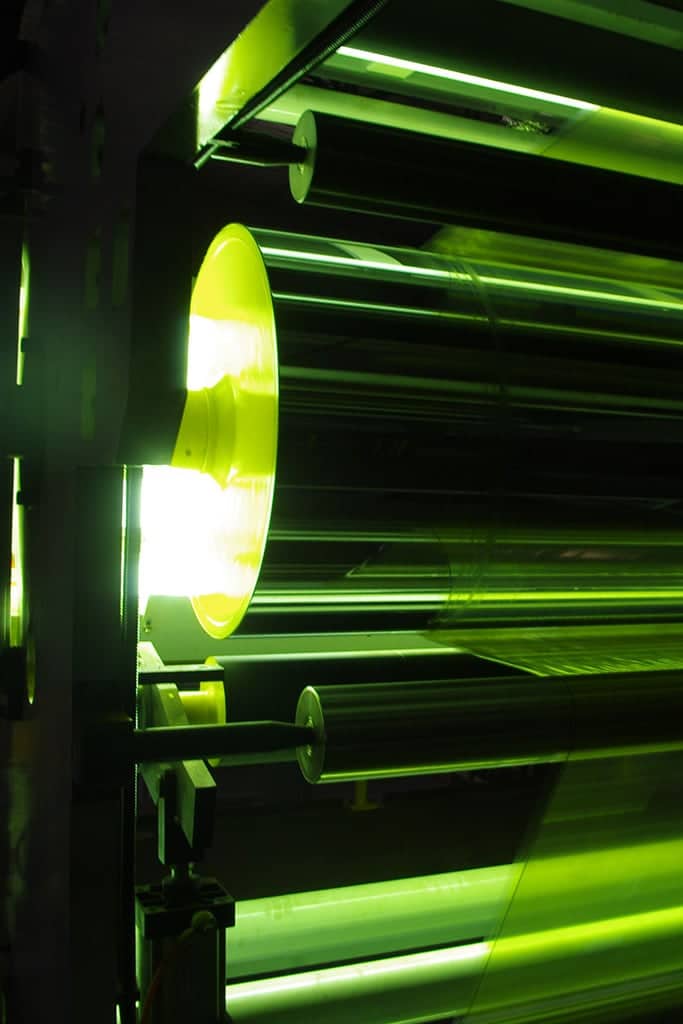

Complete Industrial Roller Reconditioning Services.

Companies that depend on roller equipment for the manufacture and assembly of goods need equipment that works hard, functions precisely, and withstands the rigor of high-production environments.

Choosing the right vendor from dozens in the marketplace is difficult. How can you be sure they understand your operation? What about components that might be necessary besides a roller? What quality assurances are available? That’s where Martin Solutions Group steps in.

Our extensive knowledge and personal dedication to meeting your needs is how we source and deliver the equipment that best suits optimum conditions for your production floor, even if that means building a custom solution, reverse engineering components, or even retrofitting older parts and industrial rollers for modern environments.

Roller Fabrication & Roller Repair

Covered Rollers & Coated Rollers

Surface Coating Processes

Custom Machine Shop & Repairs

Motor Repair, New Motor Sales & Field Reliability Services

Specialized Services & Consulting

More Up-Time.

Zero Excuses.

Martin Solutions Group knows that our services directly relate to our clients’ production performance. Successful solutions mean increased up-time and maximized profits. On the other hand, mistakes have serious consequences. We understand that better than anyone, and it shows in the standards to which we hold ourselves and our vendors accountable.

Only top-quality, industrial-grade materials and processes are used in executing any project. Precise Quality Controls and finish measurements must be used in order to meet your application’s specifications. It’s what we would demand for our own operation, which is why we’ll never settle for anything less when it comes to yours. To us, the job isn’t done until your operation is functioning the way you expect it to.

More than Rollers. Complete Solutions.

Our knowledge of vendor capabilities means we know which manufacturers produce the equipment that your application requires. More importantly, we know how all components should ideally function together so you don’t have any surprises or unnecessary down time.

Ready to Get Started?

There are dozens of ways Martin Solutions Group can help your business, but only one thing you need to do to take the first step. Get in touch with us today for a custom quote or to discuss your project in detail.

Request A Quote